What do you know about the nutrients in your spray tank? Is your liquid fertilizer made at the same facility as other chemicals? Do you know how long it sits on the shelf before you take delivery or how many country or state borders it crosses before ending up on your turf?

Have you ever asked your sales rep any of these questions? We invite you to join our #FoliarFAQ discussion and challenge you to ask! To get to know your fertilizer supplier better, here are five essential questions you should know.

Where are your products manufactured?

The Foliar-Pak product line is made in the USA, in Mendota, IL, within strategic proximity to our warehouses and customers. Our products are made throughout the year and don’t cross international borders. Local manufacturing means our orders get filled more quickly, so we don’t have to stockpile products to get what you need when you need it.

We are proud to say that Foliar-Pak is a brand that represents quality and is made in the USA!

Is anything else manufactured in your facility?

The answer is simple, nothing.

EnP, a leader in plant nutrition for nearly 30 years, manufactures Foliar-Pak products. They don’t just specialize in plant nutrition; it’s all they do, from product creation to support.

EnP manufactures both liquid and dry fertilizers. Their products are made with high-quality raw materials and supplemented with organic-based nutrients. Ingredients like food-grade amino acids, food-grade polysaccharide sugars and molasses, nitrogen, phosphorus, and potassium are the materials you will find in our manufacturing facility.

You will never find herbicides, insecticides, fungicides, or other chemicals that pose a risk for contamination in our manufacturing facility. Statistically speaking, accidents happen. Even with the strictest processes, you might make one mistake every one million times. Unlike in a facility that manufactures other inputs harmful to plants, that one-in-a-million mistake made in our facility won’t cause injury to your turf and plants.

Product performance and safety are important to us, and we don’t take chances with contamination. Foliar-Pak products will always be made at a dedicated facility that specializes in plant nutrition.

What’s in your products?

Understanding what’s in our products starts with our suppliers. Finding the right suppliers with the right products has taken years to establish. But, we’ve been able to vet most of the significant raw-material suppliers worldwide and form partnerships with the best ones. We source minerals from around the globe because we have to begin with the highest-purity starting materials possible for our sensitive reactions with amino acids to work. What this usually means is that we’re using FCC or USP-grade materials. For example, some of our amino acids lack technical grades because human food ingredients are their only primary market.

Here’s the list of quality ingredients contained in Foliar-Pak products:

- Food-grade polysaccharide sugars and molasses

- Premium cold-pressed Irish seaweed

- Food-grade amino acids

- Pharmaceutical-grade minerals

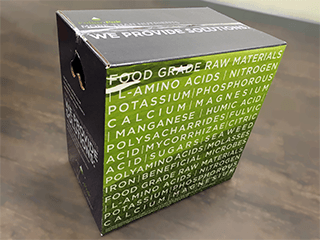

We’re so proud of the quality ingredients in Foliar-Pak products we put them on the box.

Our standards are high, and every aspect of the product—from the quality and grade of raw ingredients to the actual manufacturing process—undergoes scrutiny. Our stainless steel mixers are cleaned after every batch to ensure that what’s on the label is in each new batch. “Close enough” is not acceptable for Foliar-Pak.

Whether building precise amino-acid packages or creating an enzyme-extracted humic acid packed with beneficial plant metabolites, we are committed to constantly sourcing, developing, and manufacturing exceptional products from superior raw ingredients. This adherence to quality makes an unparalleled end-user experience.

How does your testing process work?

Our development of new products has always been driven by lab discoveries combined with field feedback. Most often, an opportunity to solve a problem has been identified in the field through conversations with our sales representatives or a superintendent (or both). Once an opportunity has been identified, we work from a formulation perspective using our chemical synthesis know-how and help from 3rd party metabolomics facilities and crystallography labs. Techniques and proprietary technologies developed for other products over the years help guide us.

When developing products, the stability of the formulations depends on many variables. So, to determine if the technology is stable enough to release or if a new liquid formulation is necessary, we place the product on a shelf, expose it to different temperatures, and see how the stability holds.

After the stability question is answered, it’s all about getting product applications out in real-world environments, which means getting the product to various locations and on different turf types. Ultimately, after the product has been in the field for some time, evaluations from end users and sales representatives located at the various sites tell us whether the product has value.

Through this research process, we may discover a new methodology or technology to incorporate into future products or updates.

Foliar-Pak Manganese with AminoPrecise is a great example of our research process, leading to a product update. For years our manganese product was simply an admixture of a manganese mineral salt and a singular amino acid, at around 5% by weight of the formulation. After working with end-users and discovering some superintendents were creating successful results using high amounts of amino acids via high rates of Foliar-Pak Foundation Forty, we realized we could make a more effective manganese product. And we did. We found a way to make a high-purity manganese amino-acid chelate, which allowed us to increase the manganese content (from 3% to 6%) while dramatically increasing the amino acid content (from 5% to about 29%). The new Foliar-Pak Manganese fully chelates the manganese ion, allowing maximum foliar entry into the plant.

What makes you great?

Driven by our passion for innovation and turf research, we have created joint ventures and relationships with some of the most brilliant PhDs in basic-science academia. This allows for an exchange of information between our world of growing turf and their world of science.

Using this diversity and richness of experience and research and leveraging the decades of combined turfgrass management experience from our distributor sales representatives, we can develop truly unique products from groundbreaking technologies. Because of these technologies, turf managers can reduce their inputs—saving money, time, labor, and the planet. We think that makes Foliar-Pak great!